Products

-

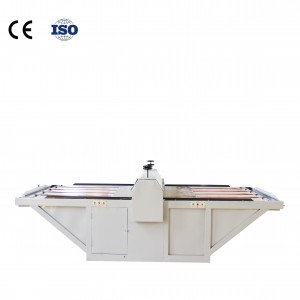

DM-DL Lift Tacking Machine

Width: 1400 – 2500 mm.

For 3 layer, 5 layer, 7 layer corrugated paperboard production line.

Features:Using five high-strength belt conveyor, closed-loop variable frequency control, automatic counting precision, smooth delivery, rapid separation and transported to the basket.

the sun wheel pressure does not damage the cardboard paper. Carbon fiber pressure strip strong wear.

This car automatic adjustment with the order structure, size, can be scattered orders, staggered stacking.

This basket of transverse using nylon plastic track output, does not damage the bottom paper.

the elevator servo control lifting cradle, reasonable weight structure, to achieve the best effect of energy-saving, basket cross, by the platform of the crawler power transfer to next procedure.

Inquiry for Our Product -

NCRW cutting off machine (helix blade)

Product Attributes

Max. design speed: Helical knives 150 m/min; 180 m/minute.

Effective width: 1400 mm – 2500 mm.

Features:

store 200 orders, replace cutter specifications quickly and accurately, non-stop for a single, and enables networked computers to facilitate production management.

knife shaft drive gears are precision forged steel high-frequency hardening, backlash-free transmission, the use of advanced keyless connection, high transmission accuracy and long life.

Using serrated knife, reducing cardboard resistance, low noise.

are used around the feed roller platen way the sun wheel, transmission smooth, uniform pressure, not easy to crush plate board or cause blockage.

The model is brake energy storage (non-dynamic braking), the energy consumption in the production process, the average power consumption is an ordinary NC cutter 1/3, save power more than 70 percent to save money goals.

Precision adjustable no gap gear to ensure precise blade engagement, running balance.

The independent pump and filter with two copper distribution in each gear position oil. -

NCBD Thin Blade Slitter Scorer

Width: 1400 – 2500 mm.

4 blade 6 scorers, 5 blades 8 scorers.

Features:can store 999 orders for a single non-stop automatically or manually for a order.

for a single fast 3-8 seconds for a single time, the two machines can be achieved with no slow down immediately for a single.

automatic tracking production line speeds, ensure their synchronization.

imports of high-quality and high-performance industrial computer programmable controller configuration, lower computer control system.

three kinds of pressure line forms: convex on concave (three lines), convex on the concave (five lines), convex on the flat, all three pressure lines can form an electric conversion. Creasing wheel depth by computer control, linear, easy to bend.

The thin tungsten steel alloy blade, blade sharp, long life of more than 8 million meters.

Brothers is computer-controlled, automatic or manual knife sharpener, you can trim the edge of the Brothers, improve production efficiency.

imported synchronous drive unit, semi-precision, long life, low noise operation. -

GM-D heavy gluing machine

Product Attributes

Width: 1400 – 2500 mm.

For 3 layer, 5 layer, 7 layer corrugated cardboard production line.

Features:glue roller surface after quenched, bore machining, surface grinding and doing balancing engraved pit style textured, coating evenly, consume less plastic.

glue roller rotation frequency motor control, frequency control to ensure the glue roller line speed and duplex synchronous machines, and can operate independently.

electric adjustment digital glue. Automatic cycle for glue, glue avoid sedimentation and viscosity stability.

pneumatic platen structure, the gap by the electric tuning. Upper and lower layer are used independently variable frequency motor drive.

sided machine speed signal measurements taken in order to achieve its synchronous operation. Man-machine interface display, easy operation.

control automatically adjusts the amount of adhesive, glue quantity with production speed, automatic adjustment, in automatic mode, you can also get in manual tuning. -

auto splicer

Width: 1400-2500 mm.

Features: Applicable maximum paper diameter: 1500 mm.

The paper holder has automatic tension control, high-speed paper splicing, and high success rate.

No tail splicing, reducing paper consumption (the overlapped part of paper and tape is only 40mm wide).

Paper pick-up, automatic rewinding, vacuum suction, convenient paper loading, automatic tension control splicing zero turnover.

Full PLC automatic control, accurate, less faults, and convenient maintenance.

When the paper is first pulled, the buffer wheel is automatically aligned and the paper is pulled easily.

Advantages of the machine The cylinder of the high-speed welding machine controls the welding torque to be normal, and the motor control will not cause stone crushing or blistering.

The maximum splicing speed is 150 m/min. -

Double preheater

Width: 1400 – 2500 mm.

Diameter: 400 mm, 600 mm, 900 mm, 1000 mm.

Features:preheat roll meets national standards for a class of pressure vessels, pressure vessel together with a certificate and inspection certificate.

After each roller surface grinding and precision grinding hard chrome plating, small surface friction, durable.

electric adjustment corners, corners can be rotated to adjust the paper is heated in the range of 360° area. -

Electric Mill Roll Stand

Purpose and Characteristics:

Single roll with four arms, Mill rolls on both arms can be bearing at the same time.

Round-plate type manual brake, the web tension is adjusted at any time.

Clamping and rotary structure set fixed torque clutch, operate safety.

Maximum paper roll diameter: φ1400 mm–φ1800mm.

Maximum weight: 2T. -

Hot-selling China Carton Box Making Machine Flexo Folder Gluer Ffg Box Line, Flexo Printing Slotting Die Cutting and Folder Gluer Inline

Control system: it adopts the full computer Delta PLC control system, which can store 999 orders; Wipe version memory, quick order change, machine zero, automatic version control precision.

Paper feeding section: the front edge paper feeding system with adsorption auxiliary four-axis roller, two rows in front and back, and light pressure paper feeding with upper and lower rubber shafts are adopted for stable and accurate paper feeding.

Printing department: ink transfer system: Dalian anilox roller, Jizhou rubber roller, excellent ink transfer and printing effect.

-

New Style China Semi Automatic High Precision Vacuum Oca Lamination Sheet to Sheet Single Sided Laminator Thermal BOPP Film Split Laminating Machine (SFML-720B)

The negative pressure design with low heat loss makes the core paper uniformly pressed and attached to the surface of the corrugating roller, so that the corrugated can be better formed. Because the pressure is uniform, the top of the corrugated can be better coated with glue, so that the single-sided corrugated paper can fit better.

-

carton making machine carton printing cardboard razor slicing edge slitter paperboard slitting thin blade slitter scorer machine

Man-machine interface – PLC control, the system for the robot operating system more humanized, simple structure, easy to maintain. 1. Manual or automatic paper feeding table can be configured 2. Automatic and independent adjustment of prepressing wheel, paper knife holder and line pressing wheel 3. Equipped with manual/automatic knife sharpening 4. Automatic adjustment of cardboard height and pressure 5. Point and fine-tune 6. Automatic counting 7. Paper parting and line pressing accura... -

Flat bed die cut machine semi automatic platform paper die cutting machine

Taiwan die cutting machine is a new generation of production of carton equipment, especially high-grade special-shaped cartons.

Table die cutting machine will edge cutting, Angle cutting, punching, slotting, wrinkling and other processes together, so that corrugated paper into the shape of the board.

The utility model is stable and reliable, reflected in the cardboard specification is accurate, no burrs, neat and tidy, safe and convenient operation and so on. -

GSYK1224 high speed water – based printing plate – free die-cutting machine

●PLC touch screen control, including automatic counting, speed, quantity display, interval, alarm lamp function.

● Selection of high quality materials and accessories. Drive roller adopts high quality steel, static and static balance, grinding and polishing, hard chrome plating.

● The main drive bearing adopts Harbin high quality bearing.

● The main control electrical appliances adopt domestic famous brand Chint.

● Keyless connection ring, reduce center wear, maintain long-term printing overprint accuracy.

● Control system: full computer PLC control system, each group using touch screen computer operation.