Products

-

Automatic carton stitching machine

QZD series automatic nail box machine is an indispensable model for the downstream process of the printing press. It consists of four parts: paper feeding part, folding part, nail box part, and counting and stacking output part. Frequency conversion speed control, simple and reliable operation. Automatic paper feeding, automatic folding, automatic correction, automatic counting, automatic stacking output. Ensure the accuracy and quality of the nail box, with high technical content, fast speed, and high efficiency nailing and forming.

Mechanical speed: 1000 nails/min.

Electric adjustment of the gap between the pressure roller and the rubber wheel.

The size of the machine’s footprint: host 15×3.5×3 meters.

The weight of the machine is about 6.5 tons.

The order-style adjustment of the whole machine can store 1000 orders.

Nail distance: 30-120mm can be adjusted arbitrarily. -

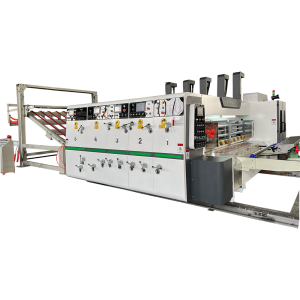

LJXC-MQYKM High Speed Printing Machine Series

Roller to Roller transfer for each unit.

• There is main touch sreen which is used for set the machine date by digital.

• Printing plate is mounting model with foot touch switch, it is fast to install.

• Each unit is equipped with Emergency Stop switch to ensure safety operation.

• Roller gaps is adjsuted by hand.

• Transmissions are using precision high hardness gears with spraying type circulating lubrication system.

• Electric element, bearing, and pneumatic element all us international brand.

-

LJXCRG Series (Full-process Adsorption, Mobile)

· The whole machine is designed and manufactured according to high requirements, reliability and safety.

· Select high-quality materials and accessories. All driving roller materials are made of high-quality steel, hard chrome plated and ground.

· Each unit fixed unit adopts vacuum adsorption conveying device, and the printing unit adopts servo control coloring to realize high-precision precision printing.

· The whole machine adopts touch screen PLC control, which can store and recall the created order data. Changing orders is faster and easier to operate.

· Remote detection of faults over the network to quickly eliminate equipment failures.

· Automatic zero reset, automatic reset.

• Adjust the gap between the conveyor roller, embossing roller and anilox roller by computer control.

· Paper dust central collection system.

-

SF-360E(320E)Drawer Type Single Facer

Design speed: 150 m/min-200m/min.

Effective width: 1400-2200 mm.

Negative pressure design, low heat dissipation, so that the pressure can evenly bond the core paper and the surface of the corrugated roller, so that the corrugated shape is better, because the pressure is even, the corrugated top is better, and the glue is uniformly applied, which makes the single-sided bonding of the corrugated better .

Quick roll change, 15 minutes, in order to replace the cart trailer containing a complete set of corrugations, it is driven by a motor, loaded into the machine, fixed on the machine base, and the corrugation can be replaced quickly and easily.

The corrugation is made of 48CRMO high-quality alloy steel, heat-treated, and the surface is grinded and plated with hard chromium or tungsten carbide. -

3 ply Corrugated Cardboard Line

Product Attributes

Width: 1400 – 2500 mm.

Speed: 60 m – 200 m/minute.

Details Attributes

The 3 layer, corrugated cardboard production line mainly consist of the following equipments:

mill roll stand, pre-conditioner, pre-heater, auto-splicer, single facer, conveying bridge, multi-ply pre-heater, duplex glue machine, double facer, slitter scorer, cutoff, conveyer and stacker, glue making system and electric control system etc. -

2 Ply Corrugator Line

2 ply corrugated paperboard production line is compose of mill roll stand, adsorptive single sided corrugated forming machine, preheater, conveying bridge, single tile vertical and horizontal cutting small hanging basket, electrical control box. Web paper after putting paper, preheating, pressing, gluing, bonding, drying, cutting, cutting continuous production, and processing into the need for single-sided corrugated board.

The production line has reasonable structure, good technology, electric heating, liquefied gas heating, heat conduction oil heating or steam heating and other ways, with high production efficiency, low labor intensity, high degree of automation, simple operation, convenient maintenance, strong adaptability and so on. -

Double servo semi automatic single nail box machine

★Mechanical speed: 800 nails/min.

★Nail distance: 30-120mm can be adjusted arbitrarily.

★Electric adjustment of the gap of the pressure paper rubber wheel.

★Effective height of worktable lifting: 900mm.

★The size of the machine area: 2.8×2.7×2 meters for the host.

★Machine weight: 2 tons.

★Order-style adjustment of the whole machine, 100 orders can be stored. -

ZJ-V5B-V6B Hydraulic Mill Roll Stand

width: 1400 – 2500 mm.

Purpose and Characteristics:The sturcture is double rotary shafts with four arms; Support two paper mill rolls on both arms at the same time.

Hydraulic control for paper mill roller up-down, clamp-open and centering.

Web tension is controlled by pneumatic brake or manual brake; Springiness chucks are optional.

Effective width: 900 mm – 2550 mm; Maximum paper roll diameter: φ1500 mm.

Maximum support weight: 3T. -

Right Angle Stacking Machine

Features:

The 14 channel welded. Electric adjustment board size, pneumatic control horizontal output board, electrically adjustable conveyor speed.

cardboard or height to the desired number of copies required by the foot switch control out of the cardboard.

longitudinal splicing using wide flat belt conveyor transport. -

Thin Knife Slitter Scorer

Width: 1400 – 2500 mm.

Electric right-left moving.

Option: electric adjusting blade.

Features:

overcome the conventional pole type, pressure line slitting phenomenon occurs when crushed cardboard cutting, cutting board smooth, quality has improved significantly.

machine can move around to adjust reduction gear.

easy to adjust the cutter and pressure lines, error ±0.5mm, automatic sharpening device, you can achieve regular sharpening, and intermittent Brothers and other features.

The machine uses 5 8 pressure wire cutter blade with tungsten alloy production, life is not less than 3 million running meters. -

DF heavy-duty conveyor bridge

Width: 1400 – 2500 mm.

Work for 2 layer, 3 layer, 5 layer, 7 layer production line.

Features:independent inverter motor lifting mechanism, PVC conveyor belt, into a single watt wavy cardboard stable rules.

All roller surface after grinding hard chrome plating.

tension control vacuum suction duct 5 inches, plus regulating valves, air flow infinitely adjustable.

electric correction device two sets of double guide posts corrective baffle positioning, screw driver, fast and accurate positioning, running smoothly.

-

Heavy Duty Single Face Papberboard Cutter

※ Technology and parameters:

1, effective width :2000mm machine speed :80m/min

2, minimum cutter length :300mm maximum cutter length :9000mm cutter accuracy :±1.5mm is uniform

※ Motor power and electrical parameters:

1, Main drive motor power :3KW full AC synchronous servo control

2. Power of drawing and feeding motor :3KW(frequency)