What types of corrugated boxes are used in industry?

The factors considered in planning the design of corrugated boxes are transport hazards, tremors, humidity, shock caused by compression, and if worse comes to worse, corrugated boxes must withstand fire. In addition to providing proper protection for the products they must accommodate, corrugated boxes must be designed in a cost-effective manner to meet customer requirements, logistics requirements and machine requirements.

The shape of a corrugated box depends on its end use. But on a large scale, here are the types of boxes typically used by the packaging and shipping industry.

Corrugated box:

Corrugated boxes are one of the most commonly used types of corrugated boxes in the industry. Its types include half corrugated carton, ordinary corrugated carton and so on. Corrugated boxes are used for packing and transporting various materials. It is also an exquisitely designed product because it produces the least amount of waste in the manufacturing process. They are usually made from a piece of corrugated cardboard that is glued, stitched or taped. In many cases, the slotted corrugated box design is the most efficient. These boxes are shipped flat and ready to use when they arrive.

Self-supporting box:

Self-supporting cases, or automatic undercases as they are known, add safety and security due to folding and locking mechanisms made of clamshell at the lower end of the cases. They are recognized for their strength and solidity. In addition, they are compressed and can be easily used for storage needs. They are best suited for assembly lines because they can be put together effortlessly and are also beneficial for conveyor systems with top-mounted automatic taper.

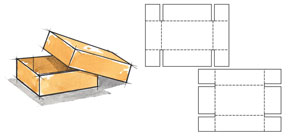

Folder box:

Folder type corrugated boxes are made of a single sheet of corrugated cardboard with a continuous, horizontal bottom. The side wall is attached at the end to the end of the corrugated board. Handles, locks and display panels can be added according to customer requirements for lifting the box design. They are located in large freestanding corrugated boxes used to pack large or irregularly shaped parts.

Rigid box:

Also known as rigid boxes, Bliss style boxes are among the strongest and most durable packaging materials available. It consists of 3 parts – two end pieces and a body that is pasted or stitched together. The flap used to make the joint may be on the end piece, the body, or both. They usually have six or more connecting rods, and once stuck, they make a very sturdy and durable frame.Dongguang Hengchuangli Carton Machinery Co., Ltd. is one of the manufacturers of corrugating carton and printing machine equipment in China. We provide high quality machines and good service for corrugating carton factories all over the world. We specialize in corrugated cartons and cardboard machines. Corrugated paper manufacturing machine, corrugated paper cutting machine, card slitter machine, flexographic printing machine, paste box machine and corrugated board die cutting machine. If you have any interest, please contact me: hengchuangli@hclmachinery.com

Post time: Apr-23-2023