LJXCQYKM Automatic Printing Machine Series

Main featrues

• Designed according the high request and the reliable function, the operation of the machine is humanization, can accomplish the setting, revision, implement, replacing and memories function in a shot time, and display with a exact data.

• All the drive rollers adopted high quality steel materials, hard chromium plating and the surface treated by lapping finish.

• The drive gears adopt high quality alloy steel, after heat treatment and lapping finish.

• The main drive roller adopt keyless connect, decrease the connection gap, guarantee the printing presicion.

• Lubricate oil automatic balance device, keep the equal oil level equal in each unit.

• Use sun feeder for feed the cardboard.

• Customer can chose use steel anilox roller or ceramic roller, the lines of the anilox roller ac so can be chosed accord the customer use.

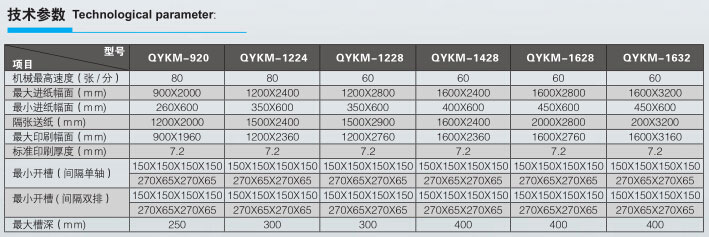

Technological parameter

· Lead edge register, adjusting suction.

· Special design for te thin sheet.

· Speed up smoothly.

· Circumferential register is motorized adjust with digital display.

· Anilox roll doctor ink evenly to make perfect print.

· Circumference poistion fix device, electromagnetic clutch breaker.

· Die-cutting pressure gap is motorized adjust.

· Setting displacement measure device for anvil roll.

· Quick change over rubber anvil, good wear-ability.

· Speed difference compensation system make line speed be synchronization, it can ensure die cutting precise.