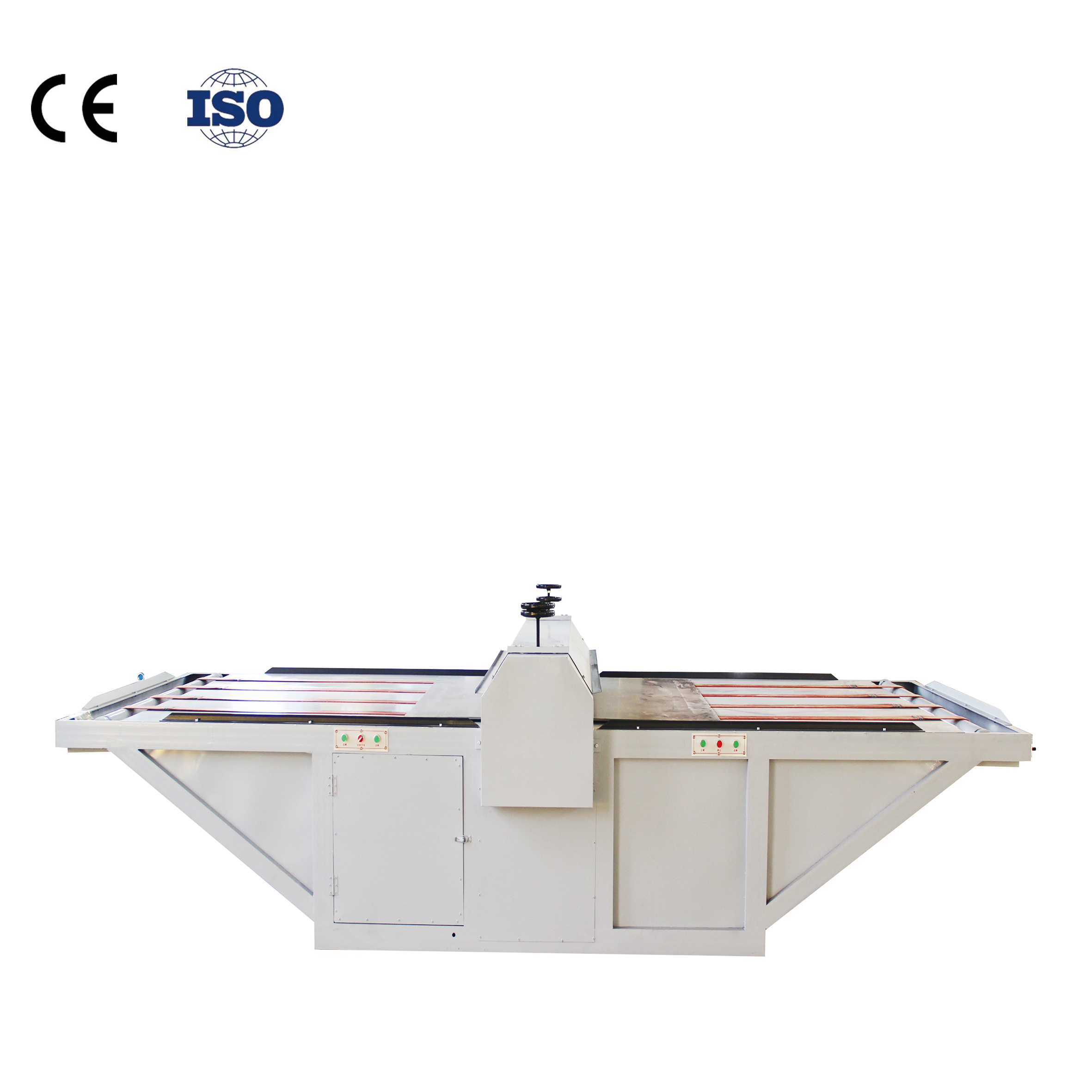

LJXC- Flat Creasing and Cutting Machine

Main structure characteristics

Sliding bearing use of high-quality casting of copper alloy, wear damping.

The flywheel torque, large pressure shear.

Airframe adopt high quality materials integrally cast, high strength. good rigidity.

Monolithic electromagnetic clutch sensitive reliable.

A monolithic continuous pressure, cut open and three functions, delay time delay can adjust at will.

Operating altitude design is reasonable, crushing open angle.

Concentrated lubrication system ensures good lubrication, reduce wear.

Safety and protection system is reliable.

|

Model |

Max, creasing Area |

Working speed |

Max. rule |

Motor power |

Overall Dimension |

|

PYQ401C |

750×520mm |

28±2 (strokes/min) |

<15m |

2.2kW |

1260×1350×1280mm |

|

PYQ203D |

930×670mm |

23±2 (strokes/min) |

<25m |

3.0kW |

1670×1670×1630mm |

|

ML1100 |

1100×800mm |

20±2 (strokes/min) |

<32m |

4.0kW |

1900×1780×1700mm |

|

ML1200 |

1200×8300mm |

20±2 (strokes/min) |

<35m |

4.0kW |

1920×2140×1920mm |

|

ML1300 |

1300×920mm |

18±2(strokes/min) |

<40m |

5.5kW |

2000×2140×2000mm |

|

ML1400 |

1400×1000mm |

17±2 (strokes/min) |

<45m |

5.5kW |

2010×2400×1930mm |

|

ML1500 |

1500×1050mm |

16±2 (strokes/min) |

<45m |

5.5kW |

2010×2400×1930mm |

|

ML1600 |

1600×1250mm |

16±2 (strokes/min) |

<50m |

11kW |

2170×2560×2230mm |

|

ML1800 |

1800×1300mm |

16±2 (strokes/min) |

<62m |

15kW |

2240×2800×2130mm |

VT Automatic cutter creaser

Function and characteristics:

High pile feeder with non-stop device for continuous operation and high efficiency.

Precise and reliable register system with adjustable front lay and left push side lay, quick set up and high accuracy.

Vacuum suction in feed and delivery system with no gripper margin, ideal or handing cardboard, E, BA flute corrugated board and plastic film.

Delivery with non-stop device for continuous operation and high efficiency.

Delivery equipped with unloading pallet jet for easy and safe operation. Batch counter and tape insert are also installed as standard device.

Misfeed and delivery check photo sensor for safe and smooth operation.

Feeder can be rolled back for easy access and quick make ready.

Technical parameter:

|

Specification |

TS-1100 |

TS-1300 |

TS-1400 |

|

Size of face plate |

850*1160 mm |

1050*1160 mm |

1150*1160 mm |

|

Max. cutting size |

1100*780 mm |

1300*900 mm |

1400*1000 mm |

|

Thickness of cutting paper |

540*360 mm |

650*480 mm |

650*550 mm |

|

Min. cutting size |

0.3~0.5cm |

0.5~0.8 cm |

0.5~0.8 cm |

|

Max. speed |

1500~2100 sheets/hour |

1200~1500 sheets/hour |

1200~1500 sheets/hour |

|

Total weight of machine |

8500kg |

9500kg |

9500kg |

|

Dimensions |

L6000*W1930*H2200 mm |

L6450*W2650*H2200 mm |

L6600*W2800*H2200 mm |