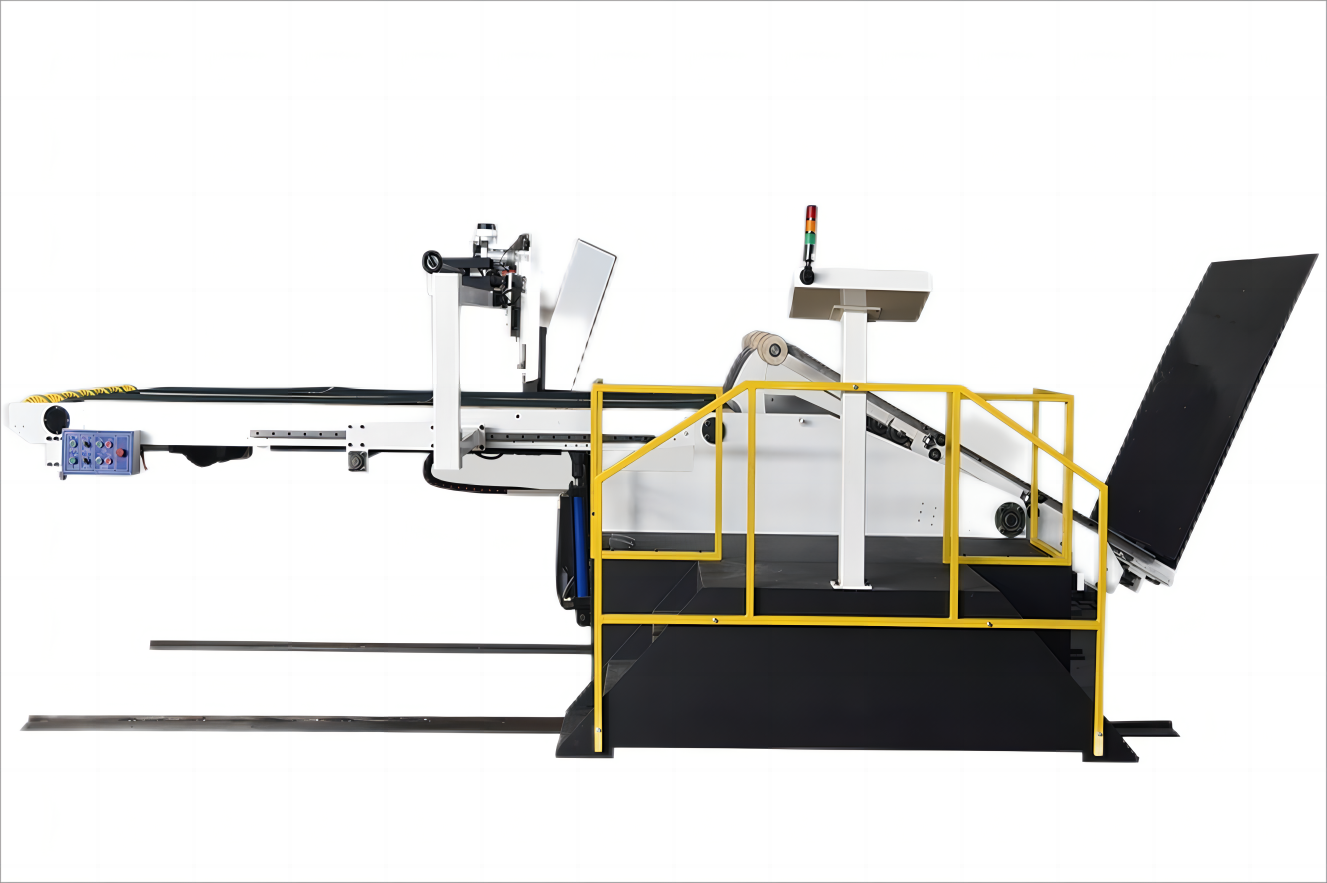

High-speed carton linkage production line

Features of the machine

- The electrical appliances and computer sofware of the whole machine adopt famous inlernational brands, and the qualty is stable andreliable. tadopts a man-machine interface, multiple touch screen controls,computer order management, easy operation,and faster order changes (p09 orderscan be stored in advance).

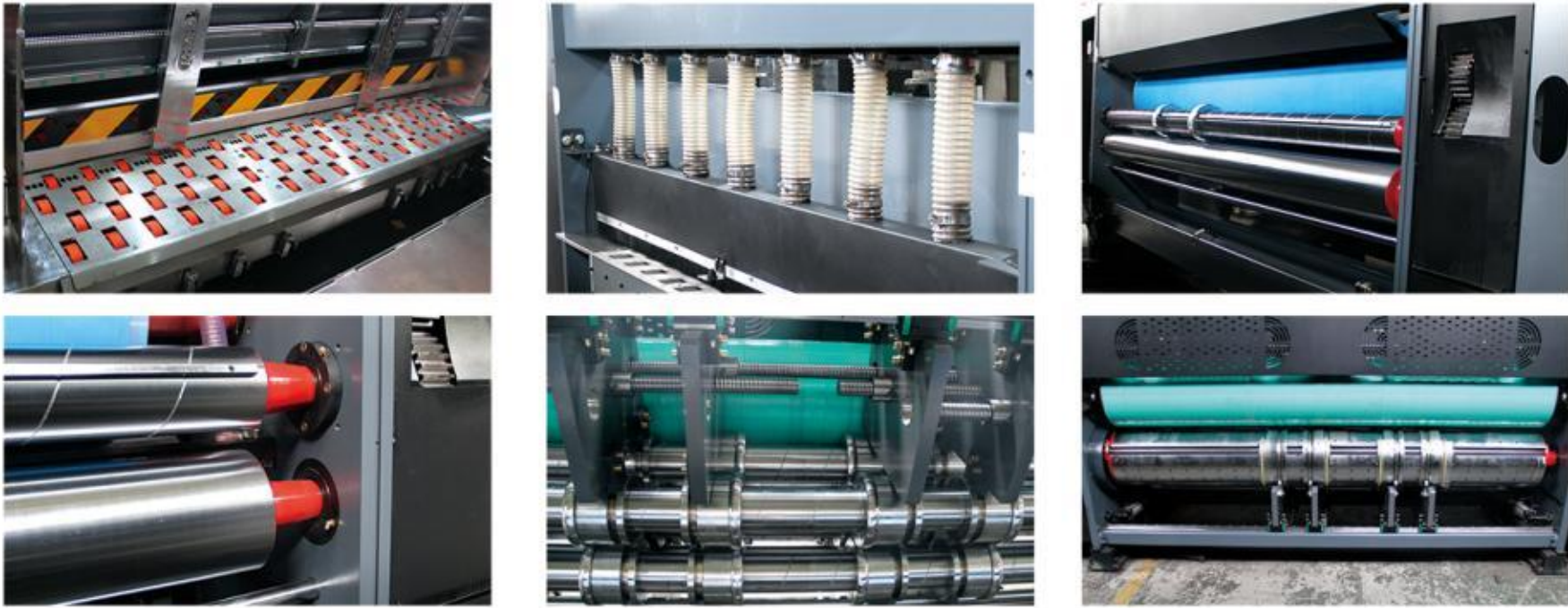

-The wall panels and important components of the whole machine are all subjected to aging treatment and tempered to eliminate the intemal stressof the metal; they are all produced by high-precision machining centers and processed by CNC grinding machines.

- The shafts and rollers of the whole machine are made of high-quaiy steel, ground and processed, high-precision computer dynamic balancecorrection, and the surface is plated with hard chrome.

-The transmission gears of the whole machine are all made of 20CiMiTiallay steel carburized and quenched, and the hardnessis HRC58-62.Aitergear grinding , the precision of six grades ensures high color registration accuracy for long-term use.

-The transmission parts of the whole machine(shaft and tooth joints) all adopt keyless connecions (expansion sleves) oeliminate connection gapsand are suitable for long-term high-speed operation with high torque.

-The transmission bearings of the whole machine and the important transmission pars all adopt reinforced seli-aligning beaings, which are easy tomaintain and have a longer service life.(Using three famous brands: "Havalo") -The transmission bearings of the whole machine and the important transmission pars all adopt reinforced seli-aligning beaings, which are easy tomaintain and have a longer service life.(Using three famous brands: "Havalo")

- The lubricating system of the whole machine adopts spray-type automatic lubrication and is equipped with an auloma ic balancing device to keepthe oil level of each unit at the same level.

- The whole machine adjusts the preset position function, paper feeding, printing, sloting, die cuting, automatic zero reset, and automati reset ofthe split and combined memory.

- The working clearance adjustment of the whole machine adopts wrench-free quick adjustment, and the adjustment is quick and convenient.- The main engine adopts frequency conversion control, which makes the start and operation more stable and energy-saving.

-Equipped with an ink shortage alarm device to monitor the working status of the ink supply system in real time.

- Optional: ceramic anilox roller; scraper ink fixing system; stacker.

Main models and Specifications