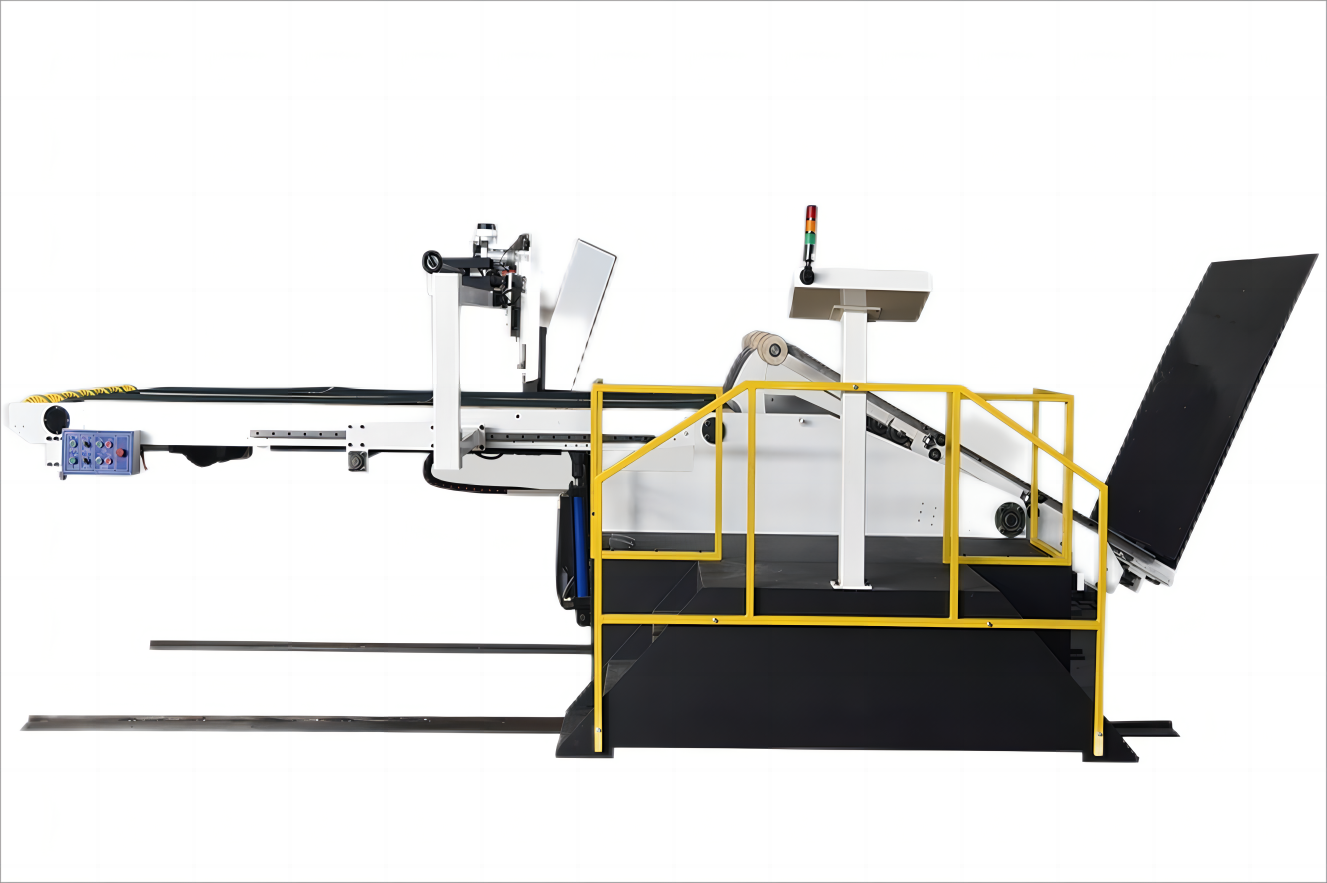

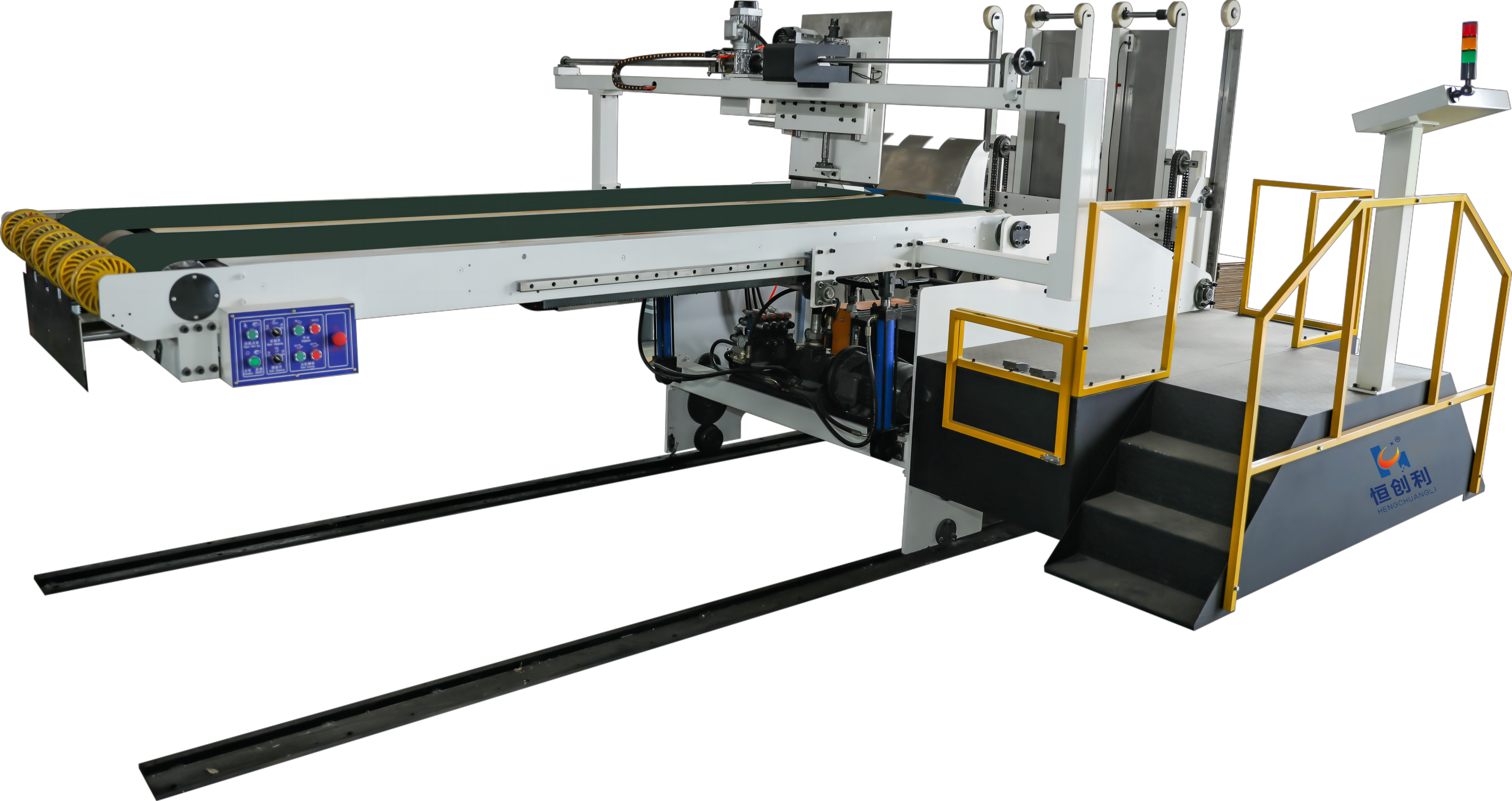

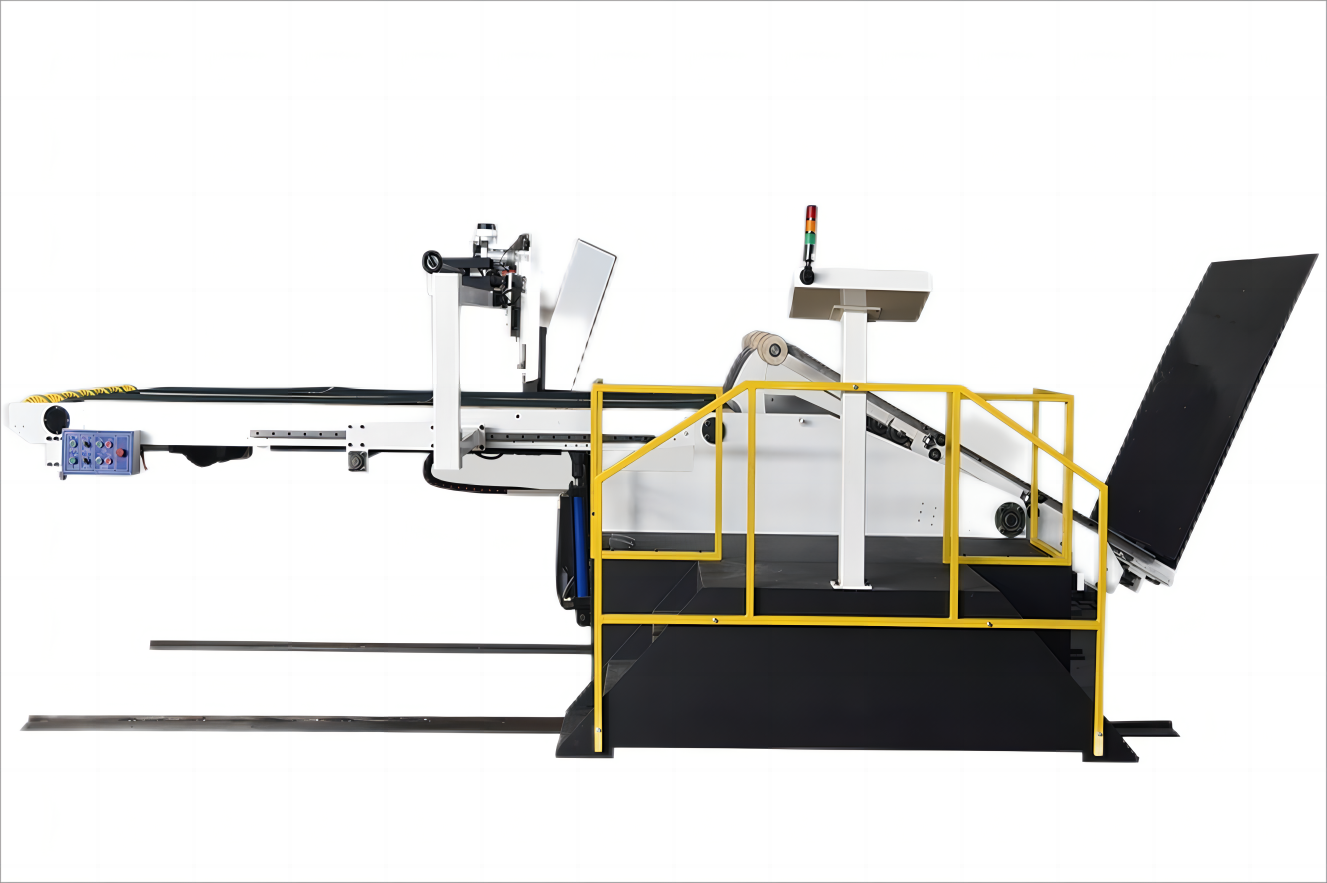

HCl-Semi-Automatic Corrugated Feeder Ink Printing Machine Supporting Equipment

| Model | HCL-1630 | HCL-1630 | HCL-2436 |

| Maximum paper speed /Minimum paper delivery size | 200 Score250x600mm | 250 Zhang / cent250x600mm | 120 Zhang / cent700x1000mm |

| Maximum paper delivery size | 1600x3000mm | 1600x3000mm | 2200x3600mm |

| Maximum load | 1600Kg | 1600-2000Kg | 1800-2500Kg |

| Maximum pile of paper height | 1800~2200mm | 1800~2200mm | 1800mm |

| Tooth fork mechanism size | 1600~1800mm | 1600~1800mm | 1800~2000mm |

| Maximum pile of paper length | 1800mm | 2000mm | 2200mm |

| Maximum-number of board stacks | 3 | 4 | 3 |

| Paper placing mode: Collapsion mode/Paper placing mode: veneer mode | √√ | √ | √ |

| Front baffle mechanism | √ | ||

| After the clapper | 1 | 1/3 | 2 |

| Paper feeding method: automatic paper feeding method | 0 | O | O |

| Size setting order | √ | √ | √ |

| operating floor | 1 | 1 | 1-2 |

| gross horse power | 12.5HP | 12.5HP | 17HP |

| Machine total weight | 4200kg | 4600kg | 5000kg |

Product features:

Suitable for equipment: printing press 09 series, 12 series, 16 series with the speed: 200 (standard) -300 pieces / minute

Single operation: compared to the traditional two paper can reduce labor costs

Production pre-arranged sheet: in the later production of the sheet, high personnel mobility

Intelligent paper supply system: with the production speed of the printing press, intelligent adjustment of the paper supply speed, stable and light paper supplement

One-button setting: size set: one-button sheet arrangement, and the height of the printing press paper feeding unit can be set according to the production conditions

Diversified paper mode: according to the size of the paper, choose veneer or front tile paper mode operation

Ergonomic design: the stair height with the best paper position Angle, configuration, easy to operate and reduce labor force

Automatic paper feeding (optional) tooth fork mechanism optional automatic paper feeding function with the front section of logistics, personnel can locate the paper without pushing the paper