Hcl-1300a /1600A front gauge automatic paper mounting machine

Product Description

■ Automatic tracking technology, according to the size of the paper automatically adjust the relevant parameters, so that the machine always operate in a good state;

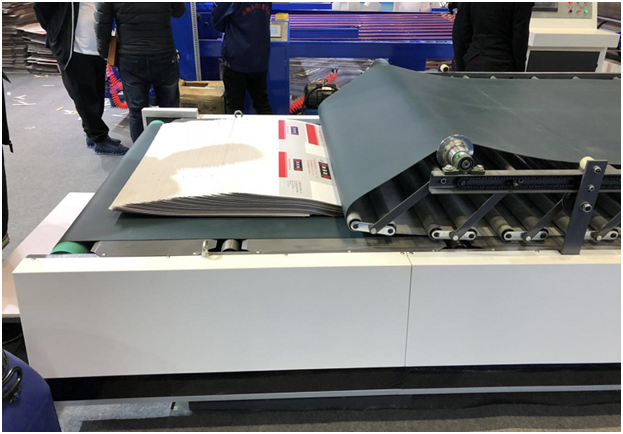

■ Unique pre-positioning system, accurate positioning, the base paper is not ahead; The lead amount of face paper is adjustable;

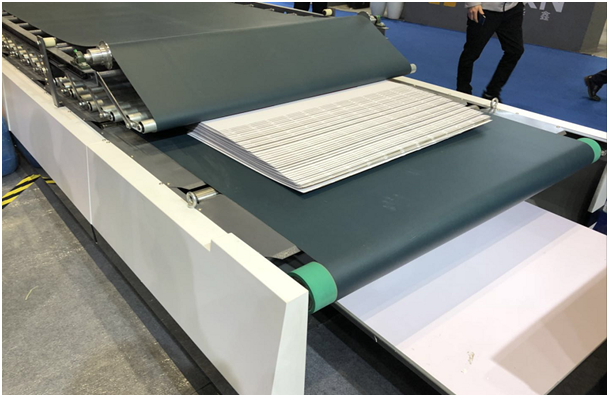

■ Equipped with high precision high-speed feida paper feeding device, enhanced paper feeding device, smooth paper feeding.

Product features

■ Automatic tracking technology, according to the size of the paper automatically adjust the relevant parameters, so that the machine always operate in a better state;

■ Unique pre-positioning system, accurate positioning, the base paper is not ahead; The lead amount of face paper is adjustable;

■ Equipped with high precision high speed feida paper feeding device, enhanced paper feeding device, smooth paper feeding.

■ The standby paper stacking table can pile up the next pile of paper without stopping, and push it into the lifting table along the guide rail, with high work efficiency

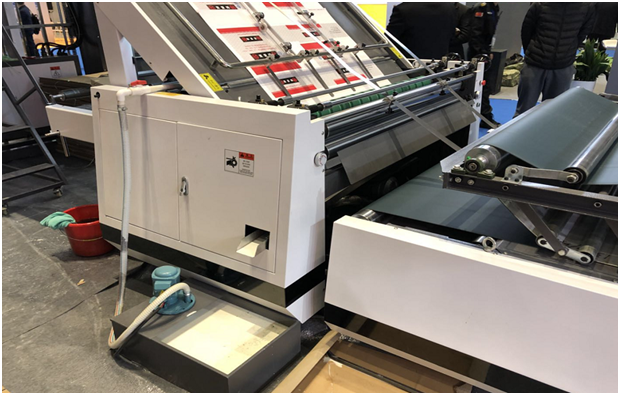

■ Imported electrical components to ensure the stability of the circuit system. PLC tracking technology, automatic fault alarm;

■ Automatic glue replenishment system can automatically replenish the lost amount of glue, and cooperate with glue recycling;

■ Automatic glue replenishment system can automatically replenish the lost amount of glue, and cooperate with glue recycling;

■ Adopt single side to adjust the pressure of each pressure roller, and equipped with pressure scale table display, replace the base paper specification adjustment in one step

| Model | HCL-1300A | HRB-1600A |

| Max size of cover face

|

1300X1250mm | 1600X1250mm |

| Mix size of cover face

|

400mmX400mm | 400mmX400mm |

| Top paper thickness | 140-800g | 140-800g |

| Bottom sheet thickness | 2/4 ply A/B/C/E/F Flute | 2/4 ply A/B/C/E/F Flute |

| Economic speed

|

0-8000pcs/h | 0-8000pcs/h |

| Precision

|

±1mm | ±1mm |

| Power

|

14kw | 14kw |

| Size

|

13.5m x 2m x 2.9m | 13.5m x 2.3m x 2.9m |

| Weight

|

About 4.5T | About 5.5T |