Products

-

High speed ink printing machine

Control system: using computer Delta PLC control system, can store 999 orders; Erase version memory, version change order fast, the whole machine to zero, automatic control version accuracy.

-

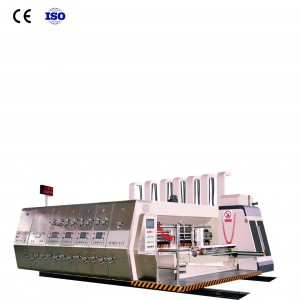

HCL-Fully servo-controlled high-definition printing, glazing, drying, slotting and die-cutting machine

-The whole machine is designed in strict accordance with high standards and high eficiency, a man-machine integration design concept, andcentralized computer control. lt has multiple protection funclions such as remote malintenance, faut sel-inspection, and alamm prompls.

All electrical and electronic components adopt European standards.

. The layout of the whole machine is mobile,the structure is stable and simple, the operation is simple, and the maintenance is convenient.. Printing vacuum suction transmission, servo control phase adjustment, to ensure the demand for high-quaity, high-dot, high-demand precision

printing products.

Equipped with an infrared drying system and a UV coating system.

- Alltransmission gears are made of high-qually alloy steel (20crMnTl) alter carburzing and precision grinding to ensure long-lemm transmissior

accuracy.(Accuracy is about equal to levels 5-6).

.All shafls and rollers are made of high-quality steel and have been quenched and tempered; dynamic and static balance are tested twice to ensure

stable and reliable high-speed operation of the equipment.

.The whole machine is made of high-qualty materials and accesories. Wall panels and important components are almade by machining centers

Optional upper printed fixed full servo drive control system. -

High speed corrugated box production line

Carton automatic gluing machine design and manufacture for printing, slotting, folding, bonding and stacking. It has the ability to carry, apply glue, fold, and form several layers automatically. PLC control, touch screen operation and pre – storage and management of orders. Its high speed production capacity, rapidly changing orders and good stability can meet our carton customers’ requirements for shorter and shorter lead times.

-

HCL-Economical High Speed Printing Slotting Die Cutting Machine

Roller to Roller transfer for each unit.

• There is main touch sreen which is used for set the machine date by digital.

• Printing plate is mounting model with foot touch switch, it is fast to install.

• Each unit is equipped with Emergency Stop switch to ensure safety operation.

• Roller gaps is adjsuted by hand.

• Transmissions are using precision high hardness gears with spraying type circulating lubrication system.

• Electric element, bearing, and pneumatic element all us international brand.

-

Hcl-1244 high speed ink printing die-cutting machine

● Designed in accordance with The European concept, functional, security more reliable.

●PLC touch screen control, including automatic counting, speed, quantity display, interval, alarm lamp function.

● High quality materials and accessories are selected. All drive rollers are made of high quality steel, balanced by static and static, and polished by grinding and plating hard chrome.

● the main transmission gear adopts high frequency quenching treatment of high quality alloy steel with 40 chromium, high precision gear grinding, high precision, strong wear resistance, smooth and reliable transmission, rockwell hardness >60 degrees.

● The main drive bearing is Harbin high quality bearing.

● The main control electrical appliances with domestic famous brand Zhengtai.

● Keyless connection ring is applied to reduce center wear and keep long-term printing overprint accuracy.

● Automatic zero and automatic reset.

● Host start protection, host can not start actively without locking, to prevent misoperation.

● All units of the machine are automatically or independently separated, electrically operated and pneumatically locked, and the alarm bell continuously rings during walking to ensure the safety of operators. Automatic braking to ensure position cannot be moved.

● Emergency stop protection, emergency stop switch is set in the machine, which can quickly stop the unit movement inside, ensuring more protection.

● Control system: the whole computer PLC control system, each group using touch computer screen operation. -

HCL-Chain type two-color slotting machine (corrugated box)

- Pre-pressing wheel device: manual slotting, crimping, and pre-pressing are completed at one time.- Electrically adjust the length, width, height, and folding part of the carton, using a digital display.- The gap between crimping wheels is manually adjusted, and the dial displays the adjusted value.

- The thickness of the slotting knife is 7mm, made of alloy steel, sawtooth heat reatment tooth shape grinding, a sharp blade, and high precision.- The slotting phase is adjusted 360 degrees by the computer’s electric numerical method.

- Select and add a hand hole mold base.

- An interlocking control switch is installed in the groove to realize an emergency stop. -

HCL-1224 fully automatic four-color die-cutting printing machine (corrugated box)

- The whole machine is designed and manufactured according to high requirements and reliable functions, and the operation of the whole machineis designed with humanization, which can be set, corrected, executed, replaced, and displayed with accurate data in a short time.

- All driving rollers are made of high-quality steel, hard chrome-plated, and surface-ground.

- The transmission gear is made of high-quality alloy steel, which is heat-treated and ground.

- The main transmission shaft adopts a keyless connection to reduce the connection gap and ensure the accuracy of printing overprint.- Automatic oil balance device to keep the oil level of each unit balanced.

- Chain feeding method.

- Anilox rol: a metal anilox roll o a ceramic aniloxrl an be selected, and the number of anilox rlscan be selected according to user requirements. -

1224-Semi-automatic two-color printing slotting die-cutting machine

Uses chain manual paper feeding, which is more suitable for factories with small production, with many options and convenient for customers to use

-

HCL- High speed corrugated box printing and slotting machine

· Host and digital display control system, can store general orders, easy to operate.

· Electronic suspension, automatic reset, quick replacement.

• Each unit is equipped with an emergency stop switch and safe operation control.

· The gap adjustment adopts electric adjustment device, which is more convenient to operate.

· High-strength design of the whole machine, spray-type circulating lubrication system.

· International components such as electrical components, main bearings and start control components.

-

HCL-Leading edge feeding three-color printing slotting die-cutting machine

· The whole machine is designed and manufactured according to high requirements, reliability and safety.

· Select high-quality materials and accessories. All driving roller materials are made of high-quality steel, hard chrome plated and ground.

· Each unit fixed unit adopts vacuum adsorption conveying device, and the printing unit adopts servo control coloring to realize high-precision precision printing.

· The whole machine adopts touch screen PLC control, which can store and recall the created order data. Changing orders is faster and easier to operate.

· Remote detection of faults over the network to quickly eliminate equipment failures.

· Automatic zero reset, automatic reset.

• Adjust the gap between the conveyor roller, embossing roller and anilox roller by computer control.

· Paper dust central collection system.

-

HCL-Corrugated carton printing and die-cutting machine

· Host and digital display control system, which can store general orders and is easy to operate.

· Electronic suspension, automatic reset, quick replacement.

• Each unit is equipped with an emergency stop switch and safe operation control.

· The gap adjustment adopts manual adjustment device, which is more convenient to operate.

· High-strength design of the whole machine, spray-type circulating lubrication system.

· International components such as electrical components, main bearings and start control components.

-

HCL-1224 High Speed Corrugated Carton Water-based Ink Printing and Die-cutting Machine

●PLC touch screen control, including automatic counting, speed, quantity display, interval, alarm lamp function.

● Selection of high quality materials and accessories. Drive roller adopts high quality steel, static and static balance, grinding and polishing, hard chrome plating.

● The main drive bearing adopts Harbin high quality bearing.

● The main control electrical appliances adopt domestic famous brand Chint.

● Keyless connection ring, reduce center wear, maintain long-term printing overprint accuracy.

● Control system: full computer PLC control system, each group using touch screen computer operation.