Factory For Taobao Printing Press - NCBD thin blade slitter scorer(Zero Pressure Line) – HengChuangLi

Factory For Taobao Printing Press - NCBD thin blade slitter scorer(Zero Pressure Line) – HengChuangLi Detail:

Structural features

The synchronous servo motor controls the cutter arrangement and wire arrangement. Automatic reset. Precise size. The change time is 3-8 seconds. When the two machines are used together, the order can be changed

immediately without decreasing speed. Store 999 groups of orders to realize automatic or manual order change without stopping the machine.

The Schneider m258 PLC control system adopts CANopen bus system, has order management function, and is equipped with the speed synchronization signal input interface with the dryer.

The human-computer interface adopts 10.4-inch color touch screen, which stores 999 groups of orders, realizes automatic order change or manual order change, and automatic fault alarm.

There are three kinds of wire pressing forms: convex to concave (three-layer line), convex to concave (five layer line), and convex to flat. The three kinds of wire pressing forms can be electrically converted. The depth of the thread pressing wheel can be controlled automatically by computer, with good alignment and easy bending.

It adopts thin tungsten steel alloy knife with sharp blade and service life of more than 8 million long meters.

The tool grinding is controlled by computer, automatic or manual. It can be used for cutting and sharpening to improve production efficiency.

The imported synchronous driving device has accurate precision, long service life and low noise.

Technical parameters

| Working width | 1400-2500mm |

| Design speed | 150m / min |

| Effective width | 1800mm |

| Design speed | 180 m / min |

| Operation direction | left or right(Determined in accordance with customer plant) |

| Mechanical configuration | Zero pressure line thin blade slitter scorer 6 knives 10 lines |

| Minimum cutting width | 135mm |

| Cutter wheel positioning accuracy | ±0.5mm |

| The minimum distance between the indentation | 0mm |

| Operation direction | left or right (determined according to customer’s workshop) |

| Mechanical configuration | zero pressure linear computer thin knife slitting machine 5 knives 8 lines |

| Minimum paper cutting width | 135mm |

| Positioning accuracy of cutter line wheel | ± 0.5mm |

| Minimum indentation distance | 0 mm |

Parameters of power motor

Tool line servo motor: 0.4KW

Wheel drive motor: 5.5kw

Wheel drive motor: 5.5kw

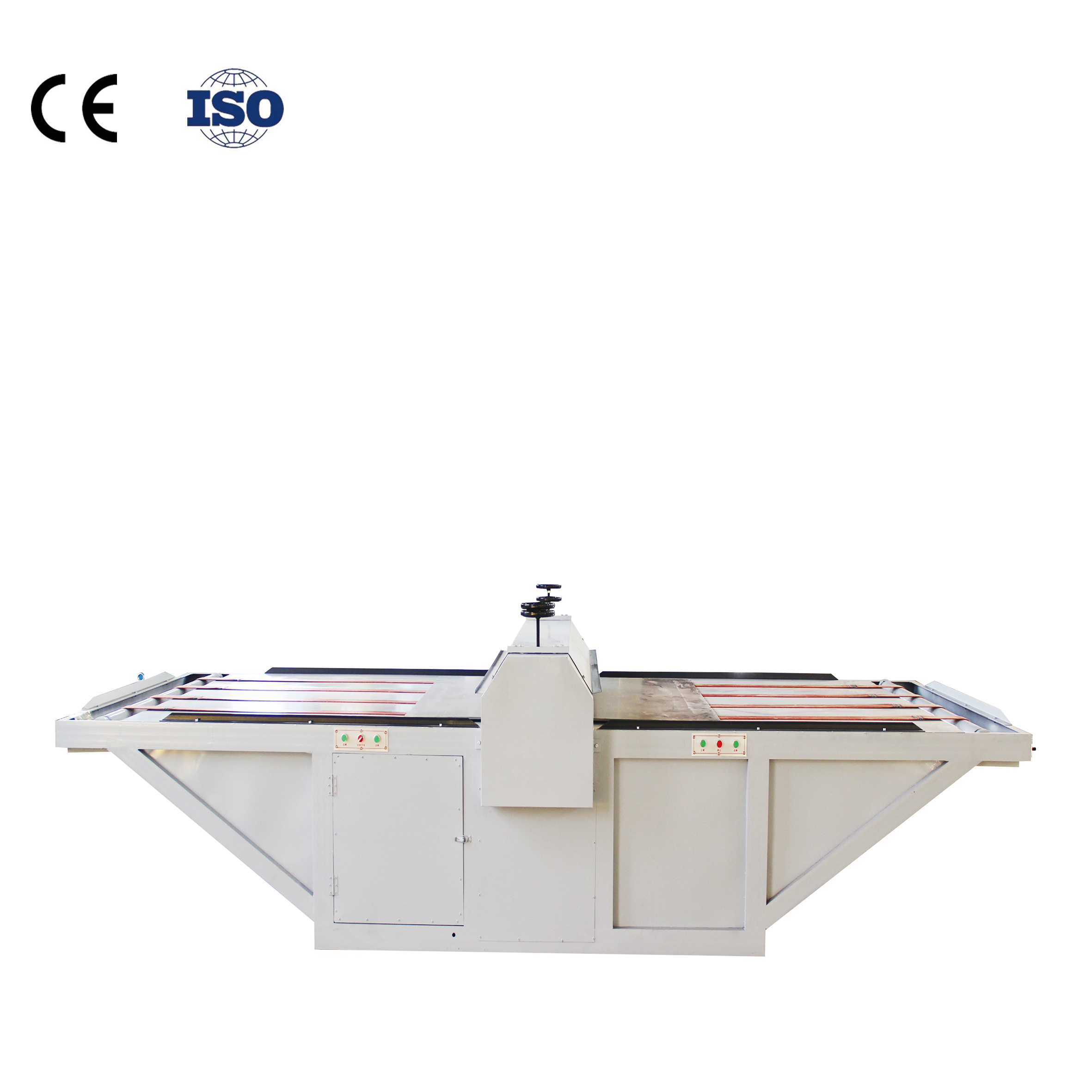

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for Factory For Taobao Printing Press - NCBD thin blade slitter scorer(Zero Pressure Line) – HengChuangLi , The product will supply to all over the world, such as: Frankfurt , Sao Paulo , Kuwait , Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.