Excellent quality Electric Paper Holder - Three ply corrugated board – HengChuangLi

Excellent quality Electric Paper Holder - Three ply corrugated board – HengChuangLi Detail:

ZJ-V5B hydraulic shaftless mill roll stand

ⅰ、Structural features:

★Adopt hydraulic drive to complete the paper clamping, loosen, remove for the medium, translation left and right and others,the lifting of the paper adopts hydraulic drive.

★Brake adjustable adopts multipoint braking system.

★Each paper rack is equipped with two paper carts that can be served simultaneously from both sides。

ⅱ、Technical parameter:

1、Paper clip range maximum : 1800mm minimum : 1000mm

2、Folder diameter maximum : 1500mm minimum : 350mm

3、Main shaft diameter of paper holder:¢240mm

4、Gas source work pressure(Mpa):0.4—0.8Mpa

ⅲ、 Hydraulic system parameters :

1、Work pressure(Mpa):16—18Mpa

2、Lifting hydraulic cylinder:¢100×440mm

3、Clamping hydraulic cylinder:¢63×1300m

4、Hydraulic station motor power:3KW –380V — 50Hz

5、Solenoid valve voltage:220V 50 Hz

RG-1-900 top(core)paper preheater RG-2-900 double preheater

ⅰ、Structural features:

★The preheating roller is designed with butterfly head, which conforms to the first class national standard of pressure vessel and has the certificate of pressure vessel.

★The roll surface after precision grinding, fine grinding and hard chromium plating processing,surface friction is small and durable。

★Electric adjustment wrap angle , wrap angle can be rotated within 360 °to adjust the paper heat area 。

ⅱ、Technical parameter:

★Effective width:1800mm

★Diameter of the preheat roller:¢900mm

★Diameter of the angle:¢110mm×2

★Steam temperature:150-200 ℃

★Steam pressure:0.8-1.3Mpa

★Motor power:250W short(S2)work system

SF-320C fingerless type single facer

- ⅰ、Structural features:

- ★Adopt hood suction structure,matched high pressure powerful fan. Gas supply and electrical control cabinet to focus on the same operation, the operating side full cover closed.

- ★High quality resin sand casting,wall thickness 200mm。Adopt independent gear box, Universal joint transmission structure.

- ★install the lifting trolley on the conveyor bridge,Need to use the car will tile roll assembly and pressure roller, such as convenient and quick.

- ★Glue roller unit structure with the overall relocation,Maintenance can sway the machine at the overall maintenance,improve the working efficiency.

- ★The humidity control apparatus equipped with a spray, so flute type to maintain good stability of deformation, avoid dry.

- ★Automatic circulation system for glue, two-cylinder pneumatic gluing device, with good cushioning effect.

- ★Glue department using integrated slide structure,Glue roller surface after grinding engraved with 32 lines and pit-style textured hard chrome plating.

- ★Corrugated roller adopt tungsten carbide dealing,diameter of the main corrugated roller¢ 320mm,Quenched→rough car→bore fine boring→shaft head shrunk-on→welding → tempering to stress→fine cars→coarse grinding→IF quenching→CNC grinding machine grinding→tungsten carbide dealing,hardness of surface is HV58degrees.

- ★Active force variable frequency motor drive, energy efficient, low failure rate.

-

- ★Glue wide electric adjust to changes in the width of the paper used。

- ★Amount of glue size with electric adjustment, touch screen display and operation of the encoder transmission coating gap, high accuracy。

- ★Power and operating parts with a safety net to ensure the safety of personnel in the operation of machinery。

- ⅱ、Technical parameter:

- ★Effective width:1800mm

- ★Operation direction:left or right(determined in accordance with customer plant)

- ★Design speed:150m/min

- ★Temperature range:160—180℃

- ★Corrugated flute:(UV type or UVV type):

- ⅲ、Roller diameter parameter:

- ★Corrugated roll diameter: up¢313mm down¢316mm ★Pressure roll diameter: ¢320mm

- ★Glue roller diameter: ¢240mm ★ Fixed paste roller: ¢140mm ★Preheater diameter: ¢402mm

- ⅳ、Powered motor parameters:

- ★Main frequency drive motor:18.5KW ★Suction motor:11KW

- ★Glue reducer:100W ★Glue adjusting motor:200W*2 ★Glue pump motor:2.2KW

ZDF conveyor bridge

Structural Features

★This part is the main beam of the 20th channel, 16-beam, angle iron 63, column, etc. are connected.

★Both sides of the security fence, ladder , high-strength save people the word pedals, ensure the safety of personnel and easy to operate.

★Pull the paper shaft surface tension axis, feeding shaft by grinding hard chrome plated.

★Vacuum tension control, 5-inch suction tube, plus regulating valves, air flow can be infinitely adjustable.

★Dual front bezel correction guide column positioning, screw driver, fast and accurate positioning, walking steadily.

ⅱ、Roller diameter parameter:

★Paper roll and a tension roller diameter:¢130mm

★Active tension roller diameter:¢85mm

★Diameter of over paper rollers and guide rollers:¢110mm

★Paper towing shaft diameter:¢110mm

ⅲ、Powered motor parameters

★Corrugated single paper lift motor:2.2KW

★The bridge adsorption motor:2.2KW

★Wide motor tune cardboard:250W

GM-20 Glue machine

ⅰ、Structural features:

★After the surface of cots is adjusted and tempered, the inner hole is processed, the dynamic balance surface is polished and there are 32 lines of concave net pattern, the glue is uniform and the amount of glue consumption is less.

★The rotation of the cots is controlled by the variable frequency motor and frequency conversion, and the frequency control ensures that the linear speed of the cots is synchronized with the two sides, and it can operate independently.

★Coating electric adjustment glue amount of digital display. Automatic circulation of glue, can effectively control the amount of glue, avoid glue precipitation, ensure good glue and save glue.

★All roller surfaces are ground after hard chromium plating.

★ The speed signal of double-sided machine is measured to realize synchronous operation with it. The rubber coating machine is displayed with man-machine interface, which can be used for data setting and easy to operate.

★Electrical design, construction production process, follow the national standards, low failure rate, easy maintenance。

ⅱ、Technical parameter:

★Effective width:1800mm ★Operation direction:left or right(determined in accordance with customer plant) ★Design speed:150m/min

★Gas supply system:0.4—0.6Mpa ★Preheat cylinder temperature range:150—200℃ ★Steam pressure:0.8—1.2Mpa

ⅲ、Roller diameter parameter:

★Glue roller diameter:¢269mm ★Over the paper roll diameter:¢110mm ★Doctor roller diameter:¢142mm

ⅳ、Powered motor parameters:

★Glue roller initiative frequency motor:3KW ★Sizing Reducer::250W ★Pressure roller clearance adjustment motor: 250W★Glue pump motor:2.2KW

SM-F type double facer

ⅰ、Structural features:

★The surface of the heating plate is grinded, the width of the hot plate is 600mm, there are 14heating plates, the cooling setting is 4 meters.The heating plate is made of vessel plate, which conforms to the national first-class pressure vessel standard, with pressure vessel certificate and inspection certificate.

★The upper conveyer belt rectifies the right and left side to adopt the pneumatic automatic correction deviation.

★Heating plate heat transfer pipe temperature control sub-four-segment, with a temperature display.

★Double cylinder S type cotton belt tensioning device is used for upper cotton belt.

★The lower belt adopts pneumatic tension, pneumatic correction

★Drive roller coated with attached wear-resistant rubber ,showed a herringbone structure,With a high, ensure smooth cardboard output。

★Main drive motor for frequency conversion motor,low-speed torque,wide speed range ,reliable, and easy maintenance.

★Hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam。

ZQS Thin knife slitting

ⅰ、Structural features:

★Overcome the conventional type of pole, cutting pressure lines appear when collapsed cardboard cut phenomenon, cutting board smooth, quality has improved significantly。

★The whole machine can remove left and right,cycloid reducer to adjust。

★Cutter and easy to adjust the pressure line, the error ± 0.5mm, automatic sharpening device, you can achieve timing Brothers, with intermittent Brothers and other features.

★The machine adopt four knives six lines,the blade is made of tungsten alloy steel, the using life is not less than 3 million running meters。

ⅱ、Technical parameter:

★Effective width:1800mm

★Design speed: 100 m / min

★Mechanical configuration: 5 knives and 8 lines

★Minimum cutting width: 135mm

ⅲ、Powered motor parameters:

★Line cutter line motor:0.4KW

★Knife wheel drive motor:5.5KW

NC-150 NC cutter helical knives

I. Structural features:

★ Can store 200 orders, quickly and accurately change tool specifications, change orders without stopping, so that the networked computer convenient production management.

The cutter shaft transmission gear adopts precision forged steel induction quenching, no clearance transmission, advanced keyless connection, high transmission accuracy.

★ Cutting machine with steel insert front edge spiral structure, blade teeth serrated. Shear, shear, shear force, long blade life.

★ All around the feeding roller adopts the sun gear pressure plate mode, smooth delivery, uniform pressure, easy to crush the plate or cause the plate blockage.

★ This type of brake is energy storage type (no energy brake), so in the production process, the average power consumption is 1/3 of the ordinary CNC cutting machine, electricity saving more than 70%, to achieve the purpose of saving money.

★ Precision adjustable without clearance gear, to ensure precise blade meshing, balanced operation.

★ Adopt independent oil pump and filter, distribute two sets of copper pipe in each gear position, supply oil, lubrication and cooling.

Knife roller: high quality forged steel material, balance, with good stability.

Two, technical parameters:

Effective width :1800 mm

★ Operation direction: left or right (according to customer factory)

★ Design speed :150 m/min

★ Mechanical configuration: computer spiral knife crosscutting

Minimum cutting length :500 mm

★ Maximum cutting length :9999 mm

★ Tool accuracy: uniform ±1mm, non-uniform ±2mm

★ Device size: LMX4.2WMX1.2HMX1.4

★ Single weight: maximum 3500kg

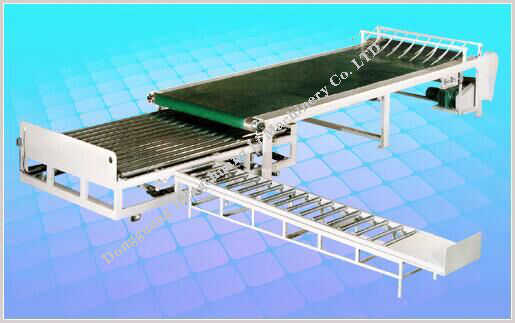

DMT-120paper sheet delivery and side conveyor

ⅰ、Structural features:

★Adopted on the 16th channel welded。Electric adjustment of cardboard the size of the lateral output pneumatic control board, electrically adjustable conveyor speed.

★Cardboard sheets to the desired number or height requirements will be controlled by a foot switch out of cardboard。

★Vertical bin using wide flat belt conveyor transport。

ⅱ、Technical parameter:

★The maximum accumulation length:3000mm

★The maximum stack height:200mm

ⅲ、Powered motor parameters:

★Main conveyor motor:3Kw adopt frequency motor

★Lateral output of the motor:1.5Kw Three-phase asynchronous motor

★Walking Motor:1.5Kw Three-phase asynchronous motor

Product detail pictures:

Related Product Guide:

Our company aims to operating faithfully, serving to all of our customers , and working in new technology and new machine constantly for Excellent quality Electric Paper Holder - Three ply corrugated board – HengChuangLi , The product will supply to all over the world, such as: Qatar , Iran , UK , Due to our dedication, our products are well known throughout the world and our export volume continuously grows every year. We will continue to strive for excellence by providing high quality products that will exceed the expectation of our customers.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.

PAPER-PREHEATER-RG-3-900-THREE-PREHEATER.png)