Products

-

7 Ply Corrugated Paperboard Line

Width: 1400 – 2500 mm. Speed: 60 m – 250 m/minute. Corrugated paperboard production line makes paper reel into paperboards, which are later used for producing corrugated boxes. A modern corrugeted paperboard production line is complete automatic. corrugating production line can produce 3, 5 corrugated paperboards of flute type A, C, BC, B, E or combinations. Stable working speed is classifyed as 150 m/min, 200 m/min, or 250 m/min. Web width extends from 1400mm to 2500 mm.

-

5 Ply Corrugated Paperboard Line

Width: 1400 – 2500 mm.

Speed: 60 m – 200 m/minute.

Corrugated paperboard production line makes paper reel into paperboards, which are later used for producing corrugated boxes. A modern corrugeted paperboard production line is complete automatic.

corrugating production line can produce 3, 5 corrugated paperboards of flute type A, C, BC, B, E or combinations. Stable working speed is classifyed as 150 m/min, 200 m/min, or 250 m/min. Web width extends from 1400mm to 2500 mm. -

3 ply Corrugated Cardboard Line

Product Attributes

Width: 1400 – 2500 mm.

Speed: 60 m – 200 m/minute.

Details Attributes

The 3 layer, corrugated cardboard production line mainly consist of the following equipments:

mill roll stand, pre-conditioner, pre-heater, auto-splicer, single facer, conveying bridge, multi-ply pre-heater, duplex glue machine, double facer, slitter scorer, cutoff, conveyer and stacker, glue making system and electric control system etc. -

2 Ply Corrugator Line

2 ply corrugated paperboard production line is compose of mill roll stand, adsorptive single sided corrugated forming machine, preheater, conveying bridge, single tile vertical and horizontal cutting small hanging basket, electrical control box. Web paper after putting paper, preheating, pressing, gluing, bonding, drying, cutting, cutting continuous production, and processing into the need for single-sided corrugated board.

The production line has reasonable structure, good technology, electric heating, liquefied gas heating, heat conduction oil heating or steam heating and other ways, with high production efficiency, low labor intensity, high degree of automation, simple operation, convenient maintenance, strong adaptability and so on. -

ZJ-V5B-V6B Hydraulic Mill Roll Stand

width: 1400 – 2500 mm.

Purpose and Characteristics:The sturcture is double rotary shafts with four arms; Support two paper mill rolls on both arms at the same time.

Hydraulic control for paper mill roller up-down, clamp-open and centering.

Web tension is controlled by pneumatic brake or manual brake; Springiness chucks are optional.

Effective width: 900 mm – 2550 mm; Maximum paper roll diameter: φ1500 mm.

Maximum support weight: 3T. -

Electric Mill Roll Stand

Purpose and Characteristics:

Single roll with four arms, Mill rolls on both arms can be bearing at the same time.

Round-plate type manual brake, the web tension is adjusted at any time.

Clamping and rotary structure set fixed torque clutch, operate safety.

Maximum paper roll diameter: φ1400 mm–φ1800mm.

Maximum weight: 2T. -

ZJ-F SHAFTLESS MILL ROLL STAND

Structural features: ★Symmetrical structure can also install two bundles of paper at the same time,Paper can be used for non-stop for a job;Adopts mechanical drive to complete the paper clamping, lifting, loosen, move on, around translational motion, etc. ★Manual disc brake, the lower limit screw, gear clamp head. ★The main frame is 14 channel steel welded with 20mm cold drawn round steel, and the length of ground rail is 4000mm. ★Each paper rack is equipped with two paper carts that can b... -

Sf-380 c adsorption type single side machine

Effective width 1800mm-2200mm Operation direction left or right(determined in accordance with customer plant) Design speed 180-200m/min Temperature range 160—200℃ Steam pressure 0.8-1.3 Mpa Corrugated flute UV type or UVV type Corrugated roll diameter up¢350mm down¢380mm Pressure roll diameter ¢385mm Glue roller diameter ¢264mm Fixed paste roller ¢140mm Preheater diameter ¢402mm Main frequency drive motor 22KW Suction motor 11KW Glue reducer 100W Glue c... -

SF-280S Single Facer

Purpose and characteristics:

Design speed: 80 m/min-100 m/min

Effective width: 1400 mm-2000 mm.

Detailed attributes: Corrugated roller: φ280mm-φ320mm.

The transmission reduction box adopts oil-immersed lubrication to reduce noise and maintain stable operation. PTZ transmission is adopted. Separate power.

Pneumatic adjustment of corrugating roller, pressing roller and rubber roller.

The cardboard conveying adopts vacuum suction method, with wind control system. Keep the grooves of the lower roller stable in the running state. -

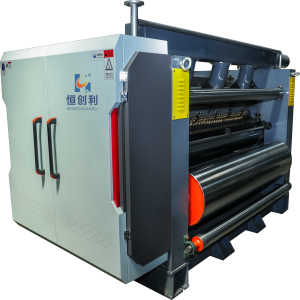

SF-320C fingerless type single facer

Design Speed: 200 m/min.

Effective width: 1400 mm – 2500 mm.The hood suction structure is adopted with high-pressure strong fan. The air source and electrical control are centralized in the same operation cabinet, and the operation side is fully enclosed and covered.

-

NC-30D Computer spiral milling cutter

structural feature: ★it can store 200 units orders,replace the cutter specifications quickly and accurately,changing orders without stop,And enables networked computers to facilitate production management. ★Knife shaft drive gears are precision forged steel induction hardening, backlash-free transmission, advanced keyless connection, high transmission accuracy。 ★Cutting machine adopts inlaid front steel blade knife spiral structure, serrated knife. scissors, shears, shear force, long blad... -

Heavy Duty Single Face Papberboard Cutter

※ Technology and parameters:

1, effective width :2000mm machine speed :80m/min

2, minimum cutter length :300mm maximum cutter length :9000mm cutter accuracy :±1.5mm is uniform

※ Motor power and electrical parameters:

1, Main drive motor power :3KW full AC synchronous servo control

2. Power of drawing and feeding motor :3KW(frequency)