Corrugated Cardboard Machine - China Manufacturers, Suppliers, Factory

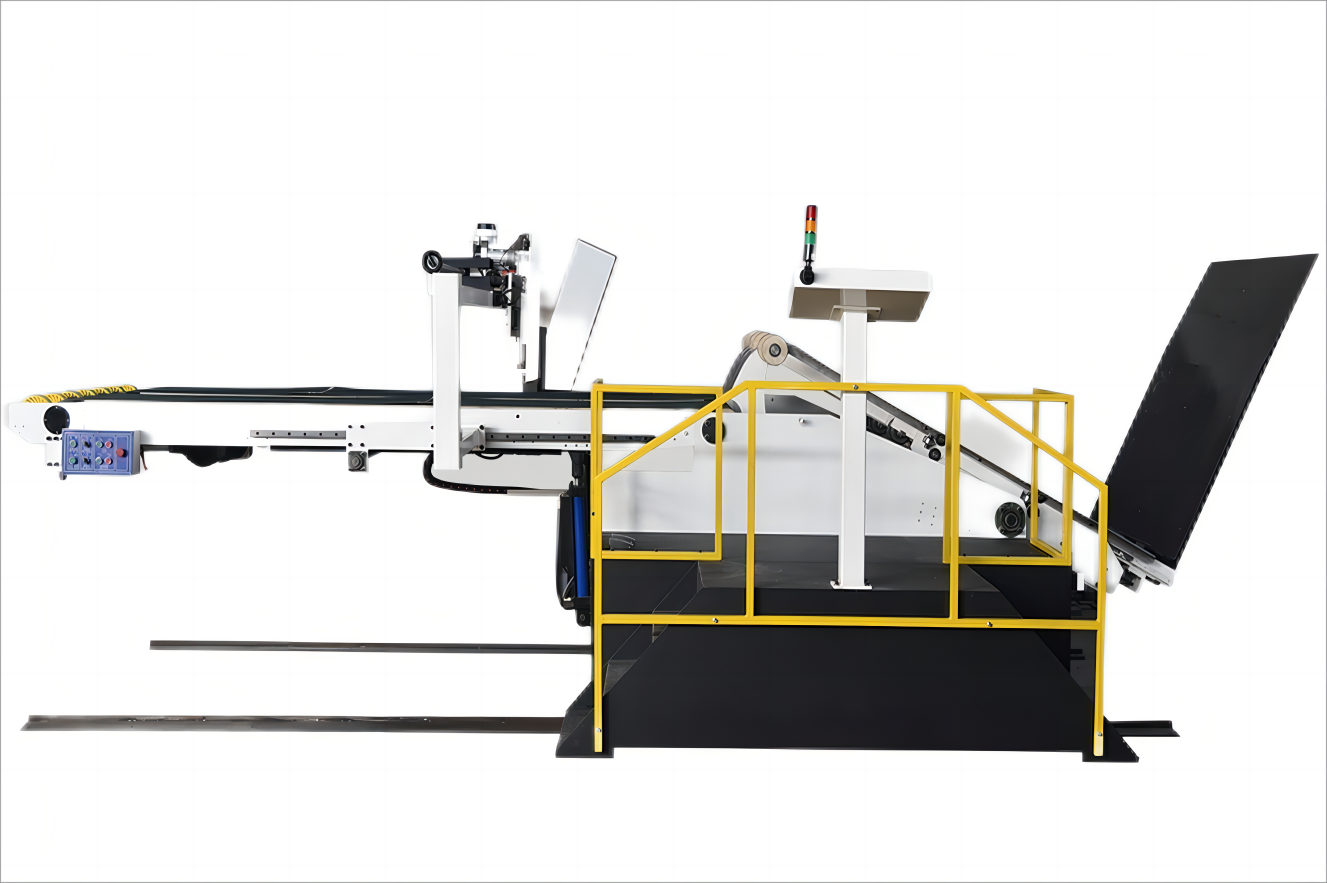

We also supply merchandise sourcing and flight consolidation companies. We now have our very own manufacturing facility and sourcing business. We could present you with almost every kind of product relevant to our solution array for Corrugated Cardboard Machine, Corrugated Bottom Lock Box Folder Gluer, Automatic Single Facer Corrugated Machine, Double Pieces Folder Gluer,Flexo Printer Folder Gluer. We are now on the lookout ahead to even larger cooperation with abroad consumers dependant on mutual added benefits. When you are interested in almost any of our products, be sure to experience cost-free to make contact with us for more facts. The product will supply to all over the world, such as Europe, America, Australia,Lahore, Niger,Anguilla, Germany.After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good products quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

Related Products