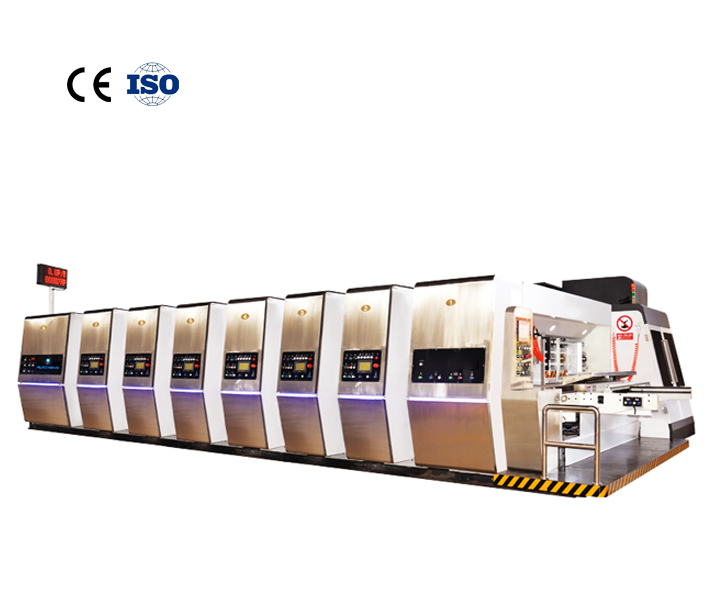

Corrugated box rotary die cutting pizza box making machine

|

Mechanical maximum speed |

150 Piece per cent |

|

economic speed |

80-100 tablets / min |

|

Maximum paper size |

1200×1800mm |

|

Send paper sizes across sheets |

1200×1800mm |

|

Minimum paper size |

700×400mm |

|

Wall plate spacing |

2000mm |

|

Standard template thickness |

25mm |

Note: The test board shall not exceed the bending coefficient of 0.015 (this coefficient refers to the poor bending height of the board when the board width is 600mm), such as the board is 600mm wide and the bending height does not exceed 9mm.

Complete machine function:

Control system: full computer PLC control system, can store 99 orders; erase memory, quick change, the machine to zero, automatic version control precision.

Paper delivery department: use the leading edge paper delivery, stable and accurate.

Die section: unique speed difference compensation device, no matter the diameter of the rubber pad changes, the speed difference compensator device can make the excellent force glue slide with the template, so that the surface speed of the glue pad is fully synchronized with the knife mode operation, so that the size of the die-cut carton and the knife mold is completely consistent.

Transmission gear: 45 # high quality alloy steel high frequency quenching treatment, high precision grinding processing, gear with high precision, strong wear resistance, stable and reliable transmission, reach the national level 6 standard.

Electrical control: using "Schneider", "Delta" stable and durable, easy to purchase.

Transfer system: standby transfer shaft and gear use key-free connection ring and cross slider transmission mechanism.

Lubrication system: each unit uses single oil pump with oil leveling device to realize circulating spray lubrication.