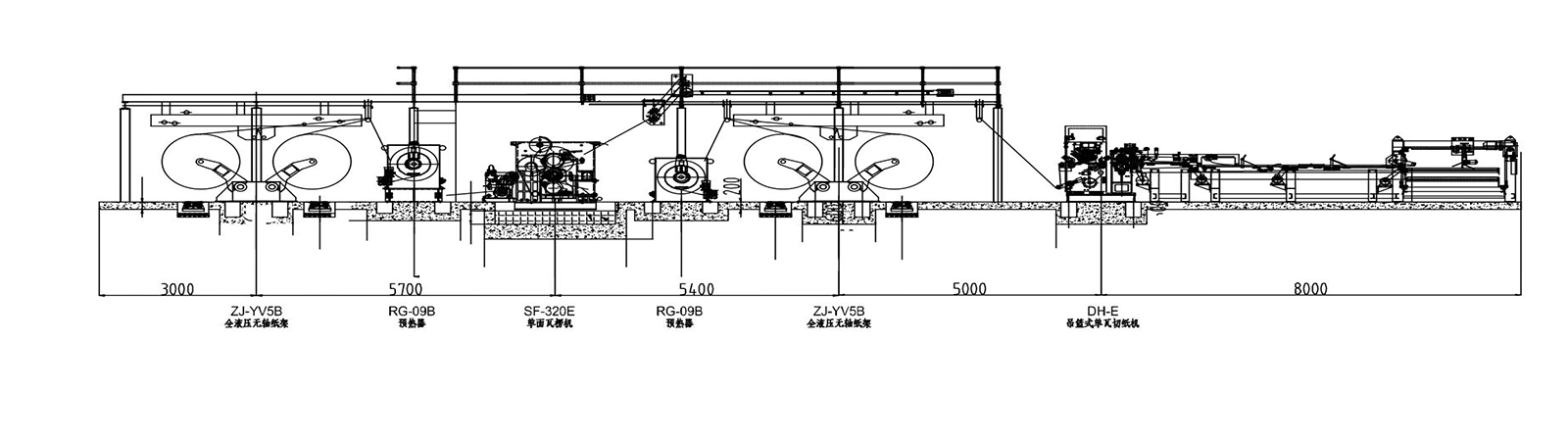

Cheap price Corrugating Cardboard Single Facer Machine - Single sided corrugated board – HengChuangLi

Cheap price Corrugating Cardboard Single Facer Machine - Single sided corrugated board – HengChuangLi Detail:

Corrugated shaftless mill roll stand

ⅰ、Structural features:

★Adopt hydraulic drive to complete the paper clamping, loosen, remove for the medium, translation left and right and others,the lifting of the paper adopts hydraulic drive.

★Brake adjustable adopts multipoint braking system.

★Each paper rack is equipped with two paper carts that can be served simultaneously from both sides.

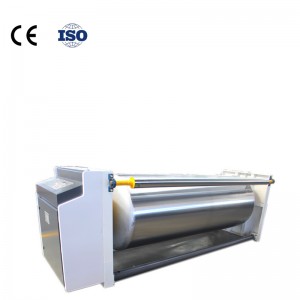

corrugated paperboard preheater machinery for paper

ⅰ、Structural features:

★The preheating roller is designed with butterfly head, which conforms to the first class national standard of pressure vessel and has the certificate of pressure vessel.

★The roll surface after precision grinding, fine grinding and hard chromium plating processing,surface friction is small and durable。

★Electric adjustment wrap angle , wrap angle can be rotated within 360 °to adjust the paper heat area .

fingerless type single facer

ⅰ、Structural features:

★Adopt hood suction structure,matched high pressure powerful fan. Gas supply and electrical control cabinet to focus on the same operation, the operating side full cover closed.

★High quality resin sand casting,wall thickness 200mm。Adopt independent gear box, Universal joint transmission structure.

★install the lifting trolley on the conveyor bridge,Need to use the car will tile roll assembly and pressure roller, such as convenient and quick.

★Glue roller unit structure with the overall relocation,Maintenance can sway the machine at the overall maintenance,improve the working efficiency。

★The humidity control apparatus equipped with a spray, so flute type to maintain good stability of deformation, avoid dry。

★Automatic circulation system for glue, two-cylinder pneumatic gluing device, with good cushioning effect.

★Glue department using integrated slide structure,Glue roller surface after grinding engraved with 32 lines and pit-style textured hard chrome plating.

★Corrugated roller adopt tungsten carbide dealing,diameter of the main corrugated roller¢ 320mm,Quenched→rough car→bore fine boring→shaft head shrunk-on→welding → tempering to stress→fine cars→coarse grinding→IF quenching→CNC grinding machine grinding→tungsten carbide dealing,hardness of surface is HV58degrees。

★Active force variable frequency motor drive, energy efficient, low failure rate。

★Glue wide electric adjust to changes in the width of the paper used。

★Amount of glue size with electric adjustment, touch screen display and operation of the encoder transmission coating gap, high accuracy。

★Power and operating parts with a safety net to ensure the safety of personnel in the operation of machinery。

ZDF conveyor bridge

★This part is the main beam of the 20th channel, 16-beam, angle iron 63, column, etc. are connected.

★Both sides of the security fence, ladder , high-strength save people the word pedals, ensure the safety of personnel and easy to operate.

★Pull the paper shaft surface tension axis, feeding shaft by grinding hard chrome plated.

★Vacuum tension control, 5-inch suction tube, plus regulating valves, air flow can be infinitely adjustable.

★Dual front bezel correction guide column positioning, screw driver, fast and accurate positioning, walking steadily.

Computer single facer corrugeated cutting and stacker

Main performance features:

★Can store 200 groups of orders, man-machine interface, screen display information, can be consulted at any time, modify, add, cancel.

★Germany Kobe servo controller control motor drive, high performance servo motor synchronous drive.

★The crosscutting machine adopts steel blade structure and hard tooth surface grinding gear to achieve no backlash transmission, high precision and long service life.

★The main engine wallboard adopts gray cast iron, with good rigidity and strong vibration resistance

★Stacking part adopts basket platform lifting, reaches a certain number of right Angle horizontal, paper is divided into four sections, a section of roller design paper flat

The output is not bent, two sections of buffer overlap with fixed length, three sections of point pneumatic separation, accelerate the output of cardboard. Improve work efficiency. The maximum stacking length is 1.6 meters. This machine is suitable for high efficiency production of color printing enterprises.

★Full servo motor control, order change fast, order change time 1-3 seconds

★Thin tungsten steel alloy knife, sharp blade, service life is more than 8 million long meters.

★Knife grinding is controlled by computer, automatic or manual, which can be sharpened while cutting to improve production efficiency

★Imported synchronous driving device, accurate, long life, low noise

★The computer control system is composed of high quality imported industrial computer and high performance programmable controller.

Product detail pictures:

Related Product Guide:

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for Cheap price Corrugating Cardboard Single Facer Machine - Single sided corrugated board – HengChuangLi , The product will supply to all over the world, such as: Peru , South Africa , Puerto Rico , During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.