Automatic carton stitching machine

1) Paper supply department

1. Adopt the belt front edge suction and paper feeding method, which is accurate and reliable

2. Adopt high-end electromagnetic clutch and electromagnetic brake system, so that the paper feeding part can be controlled separately, and the operation is simple and reliable

3. The height of the pressure roller is adjustable, suitable for cardboard with a thickness of 2-8mm

4. Linked with the folding part, frequency conversion speed regulation, paper feeding speed 0-200m/min

5. The front baffle and paper feeding belt of the paper feeding section are adjustable from left to right

Two) Folding part

1. The main motor adopts frequency conversion speed regulation system, no noise, flexible and stable speed regulation

2. Imported high-friction belts are used to convey the cardboard, which is automatically stacked

3. The folding part is equipped with a cardboard correction device and an indentation correction device

4. The folding part has two rows of adjustable inner positioning guide wheel system, which has higher forming accuracy

5. Folding speed 0-200m/min

2) Nail Box Department

1. The box without bottom and lid can also be nailed (please specify before ordering)

2. The power of nail head is servo motor, mechanical speed: 1000 nails per minute.

3. This machine can order nails, double nails, reinforced nails, double-headed tail nails, single-headed tail nails.

4. This machine can order three-layer and five-layer cartons (for seven layers, you need to declare in advance when ordering).

Three) Counting and stacking department

1. Automatic stacking and neat output

2. The main motor of the technical department can adjust the speed by frequency conversion, the speed can be adjusted, and the startup is stable and reliable

3. Use belt to transport cartons, stack neatly, speed 0-200m/min

4. Use the flap board to hit the carton, which has the function of correcting deviation, and the deviation is very small

5. Pneumatic method for counting and pushing out, PLC electronic control, reliable action, accurate and fast

6. Adopt PLC programming controller and touch screen digital control, simple operation, reliable action, input data without stopping, automatic counting

7. The output part adopts the synchronous pressing method of the bottom conveyor belt and the upper pressing belt to make the finished carton stick firmly and output neatly

adjustable:

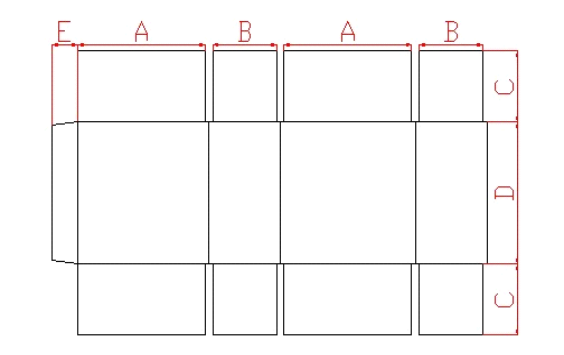

| maximum size(A+B)x2+5cm | 2500mm | minimum length A | 170mm |

| minimum size(A+B)x2 | 580mm | maximum altitude D | 900mm |

| maximum size(C+D+C) | 1200mm | minimum constructive height D | 150mm |

| minimum size(C+D+C) | 250mm | Maximum nail tongue width E | 50mm |

| Minimum swing cap C | 50mm | Maxlength A | 750mm |

| Maximum swing cap C | 380mm | minimum width | 750mm |

| maximum width B | 530mm | Number of nails | 120mm |

| Mechanical speed (nails/min) | 800 | pitch of nails |

adjustable |

Nail box part:

Japan's Mitsubishi dual-servo drive has accurate accuracy and reduced mechanical transmission parts, which can effectively reduce the mechanical failure rate.

The head reducer adopts the Taiwan Liming brand.

The gear reducer adopts the Shanghai Outer brand.

Taiwan tail wheel touch screen operation, parameter (nail distance, nail number, nail type, rear baffle) is convenient and quick to change.

The entire control system adopts the Japanese Omron PLC control system.

The rear electric baffle is driven by a stepping motor, which is accurate in size, and it is more convenient and quick to change the size.

The photoelectric and proximity switches adopt the Japanese Omron brand.

The intermediate relay adopts the French Schneider brand.

The contactor and circuit breaker adopt Taiwan Shilin brand.

The cylinder and solenoid valve adopt Taiwan Airtac brand.

The bottom mold and the blade are made of Japanese alloy tungsten steel (wear-resistant).

The entire set of nail heads are all made of Japanese mold steel and precision processed by computer gongs.

Can be nailed single nail/, double nail //, reinforced nail (// / / //two ends are double nails and the middle part is single nail)

It can be completed at one time, which can meet the different requirements of different customers for nail types.

It only takes one minute to change the size of the carton and adjust the nail distance of the carton, which greatly saves time and is easy to operate.

Can be nailed with lid box & carton box without lid (with or without lid, please specify when ordering the machine).

The front paper feeding part automatically counts, and the paper feeding table is equipped with a photoelectric sensor device, which automatically rises when feeding paper.

There is an automatic counting function in the back section, and the number of finished products can be divided and sent to the end of the conveying machine according to the set number (1-99), which is convenient for packing and bundling.